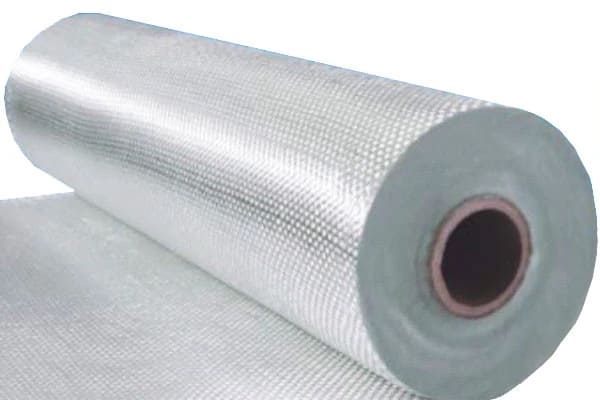

A fiberglass product is any utility that is composed of a glass reinforced polymer. Glass reinforced polymers are also known as glass reinforced plastic, fiberglass reinforced plastic or simply fiberglass. Read More…

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Product Companies

In the simplest terms, fiberglass is the combination of glass fibers and plastic material. Usually fiberglass compositions involve one or more additives, and they vary in terms of their construction and physical properties. But the defining characteristics of all fiberglass products are light weight and high strength. The strength-to-weight ratio of fiberglass is the main reason for its popularity.

\As a construction material, fiberglass sheets, panels and pipes are prized for their light weight, which makes them easy to transport and install, and for their high strength, which makes them suitable for use as building components like skylights, plumbing and even trim. Fiberglass can also be used as insulation in buildings, homes, stoves, refrigerators, furnaces and in many other contexts. Fiberglass products are also used in the construction of boat hulls, go-kart bodies, large storage tanks and automobile parts.

Because of the extensive variety of fiberglass products, an equally wide variety of fiberglass materials and production methods are necessary to accommodate them. Different fiberglass materials exhibit different physical qualities. Strength, durability, UV resistance, optical clarity and other qualities depend on the concentration and the way in which glass fibers are combined with thermoplastic materials.

Fiberglass reinforced plastic tensile strengths can range from around 55 MPa to as high as 2,300 MPa. During a fiberglass production operation, once the appropriate fiberglass material has been chosen, a fiberglass fabricator must choose the appropriate fabrication method as well. Many of the most widely utilized fiberglass fabrication methods involve molding, and the two main fiberglass molding processes are open and closed molding.

The main difference between the two options is the shape and type of the mold. In both cases though, a thermoplastic resin is heated beyond its melting point in order to make it more responsive to forming. It can be heated in a mold or in a preheating basin, as is the case when molding mandrels are used. Then, once the resin has taken the appropriate shape, it is sprayed with fiberglass and other additives if necessary. The molded product is then allowed to cool and harden.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services