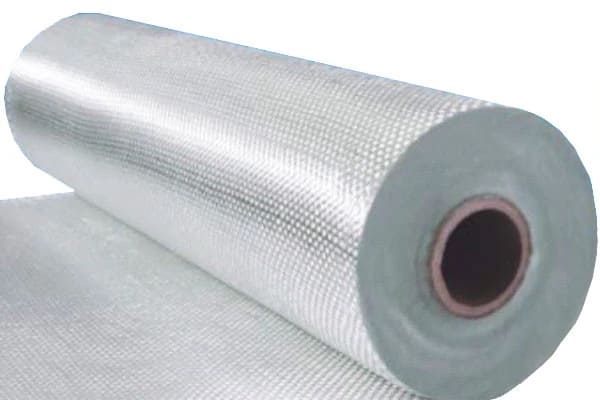

Glass fiber is used as reinforcement in fiberglass, and the glass fiber is then flattened into a sheet. Other names for it include glass-reinforced plastic and glass fiber-reinforced plastic. Read More…

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

At Advanced Composites, we take pride in our ability to deliver precision fiberglass fabrication solutions that meet the highest standards of performance and reliability. We have dedicated ourselves to mastering the properties of fiberglass and other composite materials so that we can engineer products that balance strength, durability, and lightweight efficiency.

At Fiberglass Fabricators, we take pride in being a trusted partner for innovative fiberglass solutions. Our work is rooted in a deep understanding of fiberglass as a material that offers strength, versatility, and durability across countless industries. Over the years, we have honed our capabilities to deliver high-quality fiberglass fabrication that meets the precise needs of our customers,...

Our world class steel grates are designed for longevity and usability. We can supply a plethora of secondary operations including: sawing, shearing, forming, welding, punching, drilling, plasma cutting, burning, rolling and more. Our teams have the skills to handle virtually any project that requires extensive custom fabrication. Please give us a call today to learn more information!

More Fiberglass Sheet Companies

How Fiberglass Sheets are Manufactured

Fiberglass sheet manufacturing is a sophisticated process that transforms basic raw materials into high-performance composite materials used across countless industries. The production of fiberglass, also referred to as glass fiber, starts with heating raw ingredients in a high-temperature furnace. These ingredients typically include silica, sand, limestone, kaolin clay, and dolomite. The initial step, known as batching, involves precisely weighing and measuring each component to ensure consistency in the final fiberglass product. In modern manufacturing facilities, the batching process can be automated for superior accuracy and efficiency, which is critical for quality control in industrial fiberglass production.

Once the raw materials are batched, they are introduced into a furnace where they are melted at temperatures exceeding 1,400°C (2,552°F). The large, refractory-lined furnace provides enough space for the molten glass to flow into a refiner, where it is gradually cooled and homogenized. This step is critical to ensuring the uniformity required for high-quality glass fibers used in fiberglass panels, sheets, and other composite applications.

After refining, the molten glass is directed to the bushing area—the final section of the furnace. Here, the glass is extruded through platinum alloy bushings or spinnerets, which feature hundreds to thousands of extremely small holes. As the heated glass is forced through these fine openings, it forms continuous filaments. These filaments are rapidly cooled by water jets to solidify their shape and minimize defects.

Next, the glass filaments are treated with chemical sizing agents to enhance their bonding characteristics and performance in composite matrices. The filaments are bundled together into groups called rovings, which are then wound onto high-speed winders. The weight and properties of the resulting glass fibers are determined by their yield—a function of the quantity, density, and thickness of the filaments in each roving. These fibers serve as the foundational reinforcement in a wide range of fiberglass sheet products, including fiberglass tanks and industrial panels.

The process of pulling and attenuating the molten glass into fine filaments is known as attenuation. High-speed winders apply mechanical strain, drawing the glass streams into extremely thin, strong fibers. The two primary methods for producing glass fibers are the continuous filament method, ideal for structural composites and sheet production, and the staple fiber method, used for insulation and non-woven applications. The choice of method depends on the intended use, strength requirements, and performance specifications of the final fiberglass product.

What Are the Main Types of Fiberglass?

Fiberglass sheets and composites are manufactured from different types of glass fibers, each engineered for specific properties, applications, and industry standards. Understanding these fiberglass types is essential for choosing the right material for your project or product requirements. Below are the most common types of fiberglass used in industrial, commercial, and consumer applications:

A-Glass Fiberglass (Alkali Glass)

A-glass fiberglass—also referred to as alkali glass or soda-lime glass—is the most prevalent form of fiberglass used worldwide. Known for its affordability, hardness, and chemical stability, A-glass is commonly found in everyday products such as window panes, glass jars, and bottles. Its ability to be remelted and softened makes it ideal for recycling initiatives. A-glass is especially valued for its cost-effectiveness and versatility in architectural panels and mass-produced glass products where chemical resistance is a priority but mechanical strength requirements are moderate.

C-Glass Fiberglass (Chemical Glass)

C-glass fiberglass—or chemical glass—is engineered for optimal resistance to chemical attack. Its unique composition, rich in calcium borosilicate, ensures that it maintains structural integrity when exposed to corrosive environments, including acidic and alkaline conditions. C-glass is often used as a surface tissue in the outer layer of fiberglass tanks and fiberglass pipes that are required to withstand harsh chemicals. As such, C-glass is the preferred choice for chemical processing plants, industrial piping systems, and storage tanks where chemical durability is a critical selection factor.

E-Glass Fiberglass (Electrical Glass)

E-glass fiberglass, also known as electrical glass, is specifically designed for its outstanding electrical insulating properties. This lightweight, high-strength composite material is widely used in the electronics industry and increasingly in aerospace and automotive applications where electrical insulation, strength-to-weight ratio, and thermal resistance are paramount. Due to its sensitivity to chloride ions, E-glass is not suitable for prolonged marine exposure but remains a go-to material for circuit boards, transformers, and electrical enclosures. Originally developed for electrical systems, E-glass now finds broad use in construction, transportation, and renewable energy sectors.

In addition to pure glass fibers, glass-reinforced plastic (GRP)—also known as fiberglass-reinforced plastic (FRP)—is produced by combining glass fibers with thermosetting resins. The resulting fiberglass panels and sheets offer exceptional strength, corrosion resistance, and design flexibility, making them indispensable in diverse industries such as marine, construction, chemical processing, and more.

Other Specialized Fiberglass Types

- S-Glass Fiberglass: High-strength glass fiber used in aerospace, defense, and advanced sporting goods applications for its superior tensile strength and modulus.

- AR-Glass (Alkali-Resistant Glass): Engineered specifically for use in concrete reinforcement and construction, AR-glass prevents corrosion and deterioration caused by alkaline environments.

- R-Glass and D-Glass: Specialty glass fibers optimized for unique mechanical or dielectric properties in advanced industrial applications.

What Are the Top Applications of Fiberglass Sheets?

Fiberglass sheets and panels offer an exceptional combination of lightweight strength, durability, and chemical resistance, making them highly sought after for a wide array of industrial, commercial, and residential applications. If you are exploring the benefits and use cases of fiberglass, consider the following primary applications:

- Electrical Insulation & Electronics: Fiberglass's high mechanical strength, thermal stability, and non-conductive properties make it ideal for insulating wiring, electronic circuit boards, transformers, power distribution components, and protective housings. It is extensively used in the power generation, telecommunications, and renewable energy sectors.

- Construction & Building Materials: Fiberglass sheets are a popular choice for roof panels, wall cladding, insulation, structural reinforcements, and decorative architectural elements. Their resistance to corrosion, moisture, and UV radiation ensures longevity in commercial, industrial, and residential buildings. Looking for fiberglass panel suppliers for your construction project? Explore our directory for top-rated manufacturers.

- Industrial Equipment & Chemical Processing: Due to superior resistance to corrosion and chemicals, fiberglass is extensively used in manufacturing fiberglass tanks, pipes, ducts, hoods, and containment vessels. Industries such as water treatment, chemical processing, food and beverage, and pharmaceuticals depend on fiberglass for reliable, low-maintenance equipment.

- Automotive, Marine & Aerospace: Lightweight yet strong, fiberglass composites are key materials for automotive body panels, marine hulls and decks, truck cabs, recreational vehicles, and aerospace components where weight savings, corrosion resistance, and impact strength are crucial.

- Consumer Goods & Recreation: The unique combination of strength, low weight, and moldability makes fiberglass suitable for furniture frames, divider screens, decorative trays, wall plaques, playground equipment, sports gear (such as surfboards and hockey sticks), and more.

- Transportation Infrastructure: Fiberglass is often used in bridges, highway sound barriers, railway components, and utility poles due to its durability, low maintenance, and weather resistance.

- Renewable Energy: Wind turbine blades, solar panel frames, and hydropower infrastructure often incorporate fiberglass for its strength and environmental resistance.

Why Choose Fiberglass Sheets for Your Application?

Curious about why fiberglass panels and sheets are replacing traditional materials? Here are some of the standout benefits that drive their adoption across industries:

- High Strength-to-Weight Ratio: Offers superior mechanical performance without adding significant weight, making it perfect for automotive, aerospace, and portable structures.

- Corrosion and Chemical Resistance: Withstands harsh chemicals and corrosive environments, reducing maintenance and extending lifespan—ideal for chemical plants and marine use.

- Thermal and Electrical Insulation: Naturally non-conductive, fiberglass is a preferred material for electrical and heat-sensitive environments.

- Design Versatility: Can be molded, shaped, or cut into complex forms, supporting innovative architectural and engineering solutions.

- Weather and UV Resistance: Maintains structural integrity and appearance in outdoor and exposed environments, making it suitable for both interior and exterior applications.

- Cost-Effective and Sustainable: Long service life and recyclability contribute to lower lifecycle costs and reduced environmental impact.

Frequently Asked Questions about Fiberglass Sheets

- What are the standard sizes and thicknesses of fiberglass sheets? Most suppliers offer fiberglass panels in standard thicknesses ranging from 1/16” (1.6mm) to 1” (25mm), and sheet sizes from 4’x8’ (1220x2440mm) to custom dimensions. Unsure what size you need? Contact a fiberglass sheet supplier for tailored solutions.

- Can fiberglass sheets be cut or drilled on-site? Yes, most fiberglass sheets can be easily cut, drilled, or machined using standard carbide-tipped tools. Always use proper protective equipment to avoid exposure to glass fibers.

- Are fiberglass sheets fire resistant? Many fiberglass sheets exhibit excellent fire retardant properties, especially when formulated with specialty resins. Be sure to specify fire resistance requirements when requesting a quote.

- How do fiberglass sheets compare to metal or plastic alternatives? Fiberglass offers a unique blend of strength, corrosion resistance, and lightweight properties, outperforming metals and plastics in many demanding environments. For a detailed comparison, see our materials selection guide.

- What industries use fiberglass sheets? Industries include construction, automotive, marine, aerospace, electrical, chemical processing, transportation infrastructure, and consumer goods. Looking for industry-specific solutions? Browse our supplier directory.

How to Choose the Best Fiberglass Sheet Supplier

Choosing a reliable fiberglass sheet supplier is a critical step in ensuring the success of your project. The right supplier not only provides quality fiberglass products but also offers technical support, customization options, and on-time delivery. Here’s a comprehensive approach to making the best decision for your needs:

- Define Your Requirements: Consider your application’s specifications—required sheet size, thickness, resin type (polyester, vinyl ester, epoxy), fiberglass type (E-glass, C-glass, etc.), and any special performance requirements such as flame retardancy, UV resistance, or food-grade certification.

- Research and Compare Suppliers: Use our fiberglass sheet supplier directory to find companies with demonstrated expertise in your industry. Compare business profiles, product catalogs, certifications (ISO, ASTM, UL), and customer reviews to assess their capabilities.

- Evaluate Manufacturing Capabilities: Does the supplier offer custom fabrication, CNC machining, cut-to-size services, or special finishes? Are they equipped for large volume orders or rapid prototyping? Look for suppliers who can support both standard and bespoke requirements.

- Request Samples and Technical Data Sheets: Before placing a large order, request samples and review technical documentation such as mechanical, thermal, and electrical properties, chemical compatibility, and safety guidelines.

- Assess Logistics and Support: Consider lead time, shipping options, inventory availability, and after-sales support. A reputable supplier should provide clear communication, quick response times, and comprehensive customer service.

- Request a Quote or RFQ: Use our convenient RFQ form to contact multiple fiberglass sheet companies simultaneously, saving you time and ensuring competitive pricing.

Each fiberglass sheet supplier listed in our directory features a detailed business profile highlighting their areas of expertise, manufacturing capabilities, and specialties. Our website previewer allows you to quickly browse supplier websites for further information, and our RFQ form simplifies the process of contacting multiple suppliers at once. Need help comparing options? Ask our experts for personalized recommendations based on your project requirements.

Decision Factors: What Should You Look for in a Fiberglass Sheet Supplier?

- Product Quality: Look for suppliers who adhere to strict quality standards and provide test reports or certifications.

- Customization Capabilities: The ability to offer special sizes, colors, textures, or resin systems can be crucial for specific projects.

- Lead Time and Delivery: Reliable suppliers can meet your scheduling needs, especially for large or time-sensitive projects.

- Technical Support: Access to knowledgeable engineers or sales staff helps resolve challenges and ensures optimal product selection.

- Price Competitiveness: While cost is important, balance it with quality, reliability, and after-sales service.

Ready to compare fiberglass sheet suppliers? Browse our supplier directory now to find the right partner for your next project.

Still Have Questions?

If you’re evaluating fiberglass sheets for your project, searching for the best supplier, or need technical guidance, our experts are here to help. Contact us to discuss your requirements, request a quote, or schedule a consultation. We’re committed to helping you find the right fiberglass sheet solutions for your industry and application—whether you require high-strength composites, custom-fabricated panels, or specialty resin systems.

Start your search for the ideal fiberglass sheet supplier today—leverage our comprehensive directory, in-depth resources, and expert support to ensure your project’s success!

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services