More Fiberglass Fabrication Companies

How Fiberglass Fabrication Is Performed

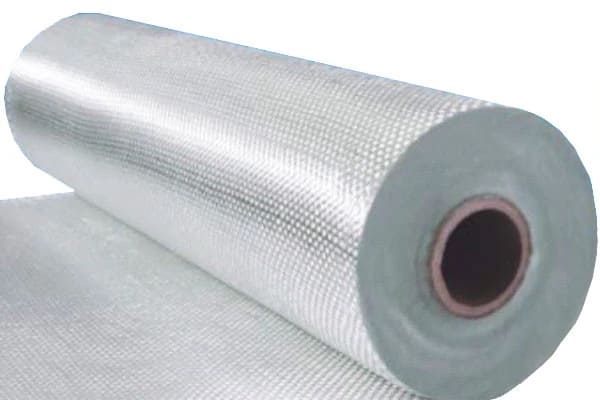

Fiberglass fabrication is a sophisticated manufacturing process that transforms raw materials into high-performance, customized composite products. The process involves several crucial steps, from material selection and fiberglass molding to finishing and quality assurance. High-quality glass fibers and compatible resins are chosen for their mechanical strength, chemical resistance, and durability. These materials form the backbone of fiberglass-reinforced plastic (FRP) composites, which are tailored for use in a range of industries, including automotive, marine, aerospace, construction, and industrial manufacturing.

After selecting the optimal glass fiber and resin systems, manufacturers employ a variety of fiberglass fabrication techniques, such as hand lay-up, spray-up, and filament winding. Each method offers unique advantages for different applications, part geometries, and production volumes. Understanding these fabrication techniques helps buyers and engineers make informed decisions about which process will best meet their project’s requirements for strength, weight, cost, and complexity.

Are you searching for the ideal fiberglass fabrication process for your custom application? Explore the pros and cons of each technique below, or browse our directory of fiberglass fabrication companies for expert assistance tailored to your needs.

Hand Lay-Up Fiberglass Fabrication

The hand lay-up process is one of the most traditional and widely utilized fiberglass fabrication methods. This manual technique involves placing layers of fiberglass mat or woven roving onto a mold, then saturating each layer with catalyzed resin to create a composite structure. The process begins with the application of a gel coat to the mold’s surface, resulting in a smooth, visually appealing finish on the final product.

Technicians carefully lay fiberglass reinforcements onto the mold and use brushes or rollers to distribute the resin evenly, ensuring thorough impregnation and optimal adhesion between layers. The composite is built up layer by layer until the desired wall thickness or structural strength is achieved. After lay-up, the part is cured, allowing the resin to harden and bond the fiberglass layers into a unified, high-strength component.

Advantages of hand lay-up include its remarkable flexibility and adaptability, making it ideal for custom or low-volume production where unique part shapes or rapid design changes are required. Hand lay-up is especially well-suited for prototyping, repairs, and applications in the marine, construction, or transportation sectors, where custom molds or small production runs are common. The process requires minimal tooling investment, which reduces upfront costs for specialized projects.

However, hand lay-up has limitations. It is labor-intensive and time-consuming, making it less efficient for high-volume or mass production. Achieving consistent thickness and fiber distribution can be challenging, resulting in variable mechanical properties. There is also a higher risk of air entrapment (voids), which can affect strength and surface finish. For applications demanding tight tolerances, high-strength consistency, or precise fiber orientation, alternative fabrication methods may be more appropriate.

Typical use cases for hand lay-up fiberglass fabrication include:

- Custom boat hulls, decks, and marine parts

- Architectural panels and decorative building elements

- Large, one-off industrial tanks or covers

- Automotive body kits and aftermarket components

Want to know if hand lay-up is right for your project? Contact experienced fiberglass fabricators to discuss your specific requirements and get expert recommendations.

Spray-Up Fiberglass Fabrication

The spray-up process, also known as chop spray or spray lay-up, is an efficient method for producing medium- to large-sized fiberglass parts at higher production rates than hand lay-up. In this technique, a specialized spray gun chops continuous fiberglass strands into short fibers and mixes them with catalyzed resin. This fiber-resin mixture is then sprayed directly onto a mold or form, building up the composite layer by layer until the required thickness and strength are achieved.

Spray-up allows for rapid coverage of large or contoured surfaces, making it particularly effective for manufacturing complex shapes and sizable components. After spraying, technicians may use rollers to compact the laminate and eliminate air pockets, further enhancing the composite’s mechanical integrity. The part is then cured, removed from the mold, and finished as needed.

Key benefits of spray-up fiberglass fabrication include:

- High-speed production for large parts, reducing labor and cycle time

- Consistent and uniform laminate quality, minimizing manual errors

- Cost-effective for moderate to high production volumes

- Suitability for producing storage tanks, tubs, shower stalls, vehicle panels, and more

However, spray-up has some drawbacks. The random orientation of chopped fibers results in isotropic properties, which can limit strength in specific directions. The process can also generate more resin-rich areas, reducing the strength-to-weight ratio compared to precisely oriented laminates. Additionally, the requirement for specialized spraying equipment and skilled operators may increase startup costs for some businesses.

Are you evaluating spray-up versus other fiberglass fabrication methods? Learn more about the alternatives and consult with industry specialists to determine the best fit for your project’s scale and performance needs.

Filament Winding Fiberglass Fabrication

Filament winding is a precision-driven fabrication method designed for producing cylindrical, tubular, or spherical fiberglass-reinforced structures with unmatched strength and consistency. In this process, continuous fiberglass filaments are impregnated with resin and wound under controlled tension onto a rotating mandrel in specific patterns (such as helical, hoop, or polar windings). After winding, the part is cured and then the mandrel is removed, resulting in a seamless, high-strength composite structure.

This method offers exceptional control over fiber orientation and laminate thickness, making it possible to engineer parts for maximum performance under specific loads. Filament winding is widely used in industries requiring pressure-resistant, lightweight, and durable parts, such as aerospace, defense, oil & gas, chemical processing, and municipal infrastructure.

Advantages of filament winding include:

- Superior mechanical properties due to precise fiber alignment

- Excellent repeatability and scalability for large production volumes

- Reduced risk of delamination or weak joints thanks to seamless construction

- Material efficiency and minimal waste generation

Limitations of filament winding are primarily related to its specificity. It is best suited for parts with simple, rotationally symmetrical shapes (e.g., pipes, tanks, pressure vessels). The equipment investment can be significant, and complex, non-tubular geometries are difficult to achieve with this method.

Looking for high-performance fiberglass pipes, pressure vessels, or aerospace-grade cylinders? Find leading filament winding companies and explore how this method can meet your demanding specifications.

Choosing the Appropriate Technique

Selecting the optimal fiberglass fabrication method requires a thorough analysis of several factors. The decision impacts not only the quality and performance of the final product but also production efficiency, cost, and long-term reliability.

Key decision factors include:

- Part geometry and complexity: Hand lay-up excels at custom, complex shapes; filament winding is preferred for cylindrical forms; spray-up is ideal for large, relatively simple surfaces.

- Mechanical and environmental performance: Consider required strength, stiffness, impact resistance, corrosion resistance, and exposure to environmental extremes.

- Production volume and speed: Hand lay-up for prototyping or small batches; spray-up and filament winding for mid- to high-volume manufacturing.

- Budget and cost-effectiveness: Analyze tooling costs, labor requirements, and material yield for each method.

- Resource and equipment availability: Evaluate in-house capabilities versus outsourcing, and the need for specialized machinery or skilled labor.

- Regulatory and safety considerations: Factor in applicable industry standards, environmental regulations, and workplace safety protocols.

Each project is unique—balancing these factors ensures the selected fabrication process aligns with your application’s technical requirements and business objectives.

Need help choosing a fiberglass fabrication technique? Request expert guidance from our network of fiberglass manufacturers and get matched with companies specializing in your industry and application.

Performers of Fiberglass Fabrication

When planning a fiberglass fabrication project, buyers must decide whether to manufacture in-house or outsource to specialized fiberglass fabricators. Each approach offers distinct advantages and should be evaluated based on the project’s scale, complexity, and requirements.

- In-house fabrication: Provides complete control over production processes, quality standards, and lead times. Best suited for organizations with established manufacturing infrastructure, skilled technicians, and ongoing demand for fiberglass components.

- Outsourced fabrication: Enables access to expert knowledge, advanced equipment, and economies of scale. Contracting with experienced fiberglass fabrication companies is often more cost-effective for complex, custom, or one-off projects, or when specialized certifications are required.

When comparing fiberglass fabrication providers, consider their track record, certifications, technology investments, and ability to meet your delivery schedules and quality expectations. Browse our vetted directory to find top-rated fiberglass fabrication partners and request competitive quotes.

Have questions about outsourcing versus in-house manufacturing? Learn more about common decision-making criteria or contact our experts for tailored advice.

Regulations and Requirements for Fiberglass Fabrication

Compliance and safety are critical in fiberglass fabrication. The industry is governed by a range of regulations to protect workers, ensure product quality, and minimize environmental impact. Buyers and manufacturers must remain up-to-date with federal, state, and local requirements for occupational health, hazardous material handling, and facility operations.

Key regulatory requirements include:

- OSHA standards: The Occupational Safety and Health Administration requires comprehensive training for all personnel handling resins, catalysts, and fiberglass reinforcements. Employers must implement safe work practices, provide personal protective equipment (PPE), and adhere to the Hazard Communication Standard (HCS) for chemical labeling and safety data sheet (SDS) management.

- EPA environmental regulations: The Environmental Protection Agency sets strict guidelines for air quality, emission control, and waste management. Fiberglass fabrication can release volatile organic compounds (VOCs) and particulates—proper ventilation, emission capture, and responsible disposal practices are mandatory.

- Industry-specific standards: For sectors such as aerospace, automotive, marine, and construction, additional certifications and quality assurance protocols may apply. These include ISO 9001, AS9100, ASTM, and other product-specific standards that govern testing, traceability, and performance benchmarks.

- Local zoning and building codes: New fabrication facilities must comply with municipal regulations regarding site location, fire safety, hazardous material storage, and impact on surrounding communities.

Staying compliant not only ensures legal operation but also builds trust with customers and end users. Learn more about regulatory requirements for fiberglass products or reach out to industry associations for the latest compliance updates.

Wondering how to ensure your fiberglass products meet all relevant standards? Ask about quality control and certification programs available for your industry.

Overcoming Considerations Regarding Fiberglass Fabrication

While fiberglass fabrication offers substantial benefits, it is important to recognize and proactively address potential drawbacks and operational challenges. Key considerations include worker health and safety, environmental responsibility, and design limitations.

Worker safety: The fabrication process can expose workers to airborne glass fibers, resin fumes, and VOCs, which may cause respiratory irritation or long-term health issues. To mitigate these risks, leading manufacturers implement rigorous safety programs, including engineering controls (ventilation, dust collection), PPE (respirators, gloves, protective clothing), and regular safety training. Periodic air quality monitoring and adherence to OSHA guidelines are also essential.

Environmental impact: Fiberglass waste can be challenging to recycle, and improper disposal contributes to landfill buildup. Progressive companies are exploring recycling solutions for composite materials, such as mechanical grinding, thermal processing, or reusing fiberglass in secondary applications. The development of bio-based resins and more sustainable reinforcement materials is also gaining momentum within the composites industry.

Design and manufacturing constraints: Traditional methods like hand lay-up may limit the ability to produce very intricate, high-tolerance, or repeatable parts. However, integrating advanced CAD/CAM software, CNC machining, and automated lay-up or robotic spray-up systems significantly expands the potential for precision and complexity in fiberglass component manufacturing.

Have environmental or safety concerns about your fiberglass project? Ask about green manufacturing practices and workplace safety solutions that leading fiberglass fabrication companies offer.

Continuous improvement and innovation are driving the industry forward, making fiberglass fabrication safer, more efficient, and more sustainable. By partnering with experienced, forward-thinking manufacturers, you can ensure your projects benefit from the latest advancements and best practices.

Benefits of Fiberglass Fabrication

Fiberglass fabrication delivers a suite of compelling advantages that make it a preferred solution for manufacturers, engineers, and product designers worldwide. These benefits address key buyer concerns such as performance, cost, longevity, and sustainability.

- Outstanding strength-to-weight ratio: Fiberglass composites are significantly lighter than metals while offering comparable or superior tensile and flexural strength. This directly translates into improved fuel efficiency for vehicles, easier handling and installation, and reduced structural load in buildings and infrastructure.

- Exceptional durability: Fiberglass resists corrosion, UV radiation, moisture, and harsh chemicals, making it ideal for outdoor, marine, and industrial environments. Long service life and minimal maintenance requirements contribute to a lower total cost of ownership.

- Design flexibility: The ability to mold fiberglass into virtually any shape or contour enables innovative designs, aerodynamic forms, and the integration of complex features without sacrificing strength or performance.

- Superior electrical and thermal insulation: Fiberglass is inherently non-conductive, making it an excellent choice for electrical enclosures, switchgear, insulators, and thermal barriers in demanding industrial or utility settings.

- Customization and performance tuning: By varying fiber orientation, resin chemistry, and reinforcement type, manufacturers can tailor the composite’s properties—such as rigidity, impact resistance, or fire retardance—to meet precise application needs.

- Cost-effectiveness for long-term value: Despite higher initial material costs compared to some alternatives, the reduced maintenance, lighter weight, and improved efficiency often result in significant lifecycle savings.

- Sustainability and recyclability: Ongoing research into recyclable composites, eco-friendly resins, and closed-loop manufacturing processes is making fiberglass fabrication an increasingly green choice for responsible manufacturers.

Discover how fiberglass fabrication can elevate your project’s performance and sustainability profile. Connect with leading suppliers for custom solutions and cost-benefit analyses tailored to your industry.

Curious about which benefits matter most for your application? Explore real-world case studies of fiberglass fabrication in different sectors, from renewable energy to transportation and beyond.

Applications of Fiberglass Fabrication

Fiberglass fabrication underpins innovation and efficiency in a wide array of industries. Its versatility, durability, and customizable properties have made it indispensable for both large-scale infrastructure projects and highly specialized components. Common applications of fiberglass fabrication include:

- Construction and architecture: Roofing panels, façade cladding, window frames, skylights, and decorative elements—offering design freedom, weather resistance, and low maintenance.

- Transportation: Automotive body panels, truck fairings, RV components, railcar interiors, and bus exteriors—improving fuel efficiency and reducing emissions through weight savings.

- Aerospace and aviation: Aircraft interiors, cargo liners, radomes, and structural supports—meeting stringent strength, weight, and flammability standards.

- Marine and boating: Boat hulls, decks, superstructures, bulkheads, and marine hardware—delivering corrosion resistance and long-term performance in harsh saltwater environments.

- Sports and recreation: Kayaks, canoes, surfboards, snowboards, hockey sticks, golf club shafts, and fishing rods—maximizing strength, flexibility, and durability for high-performance sporting goods.

- Industrial and manufacturing: Chemical storage tanks, process piping, ductwork, machine guards, and custom enclosures—providing robust solutions for aggressive or corrosive conditions.

- Renewable energy: Wind turbine blades, solar panel supports, and hydroelectric infrastructure—enabling lightweight, large-scale energy capture and transmission structures.

- Electrical and electronics: Electrical enclosures, switchgear, transformer housings, printed circuit board substrates, and insulating panels—ensuring safety and reliability in high-voltage environments.

Looking for an industry-specific solution? See how fiberglass fabrication is transforming your sector or contact companies specializing in your application for tailored advice and quotes.

Choosing the Right Fiberglass Fabrication Business

Finding a trustworthy and capable fiberglass fabrication company is essential for the success of your project. With so many providers offering a range of processes, certifications, and industry expertise, it’s important to compare multiple options before making your decision.

Our comprehensive directory allows you to:

- Review company profiles: Evaluate each fabricator’s capabilities, experience, and specialties—whether you need hand lay-up, spray-up, filament winding, or advanced composite solutions.

- Request quotes directly: Use our RFQ (Request for Quote) form to contact multiple companies with your project specifications and receive competitive pricing, turnaround times, and technical consultations.

- Preview company websites: Quickly assess each provider’s portfolio, certifications, production capacity, and customer focus.

- Filter by application or sector: Find manufacturers with a proven track record in your industry, from marine and aerospace to construction and industrial markets.

Ready to start your search? Browse top fiberglass fabrication businesses today, or ask for expert recommendations based on your project’s requirements and priorities.

Still have questions about selecting the best fabrication partner? Explore our buyer’s guide for tips on evaluating capabilities, quality assurance, compliance, and value-added services.

What are the primary fiberglass fabrication techniques?

The main fiberglass fabrication techniques are hand lay-up, spray-up (chop spray), and filament winding. Each method has unique advantages for different applications, part geometries, and production volumes. Hand lay-up is ideal for custom shapes and prototyping, spray-up provides high-speed production for large parts, and filament winding is used for making cylindrical or tubular structures with high precision and strength.

What are the advantages and limitations of hand lay-up fiberglass fabrication?

Hand lay-up offers flexibility and adaptability for custom or low-volume production, requires minimal tooling investment, and is suitable for prototyping and repairs. Its limitations include being labor-intensive, time-consuming, and less efficient for high-volume runs, leading to potential inconsistencies in thickness and fiber distribution.

How does the spray-up process differ from hand lay-up in fiberglass fabrication?

Spray-up uses a spray gun to chop fiberglass strands and mix them with resin before spraying the mixture onto a mold. This method enables faster production of large or complex parts and offers more uniform laminate quality compared to hand lay-up, but it requires specialized equipment and produces fiber orientation that can limit directional strength.

What are the main factors to consider when choosing a fiberglass fabrication method?

Important considerations include part geometry and complexity, mechanical and environmental requirements, production volume, budget, available resources and equipment, and any applicable industry or safety regulations. Balancing these factors helps to select the method that best meets a project’s technical and business objectives.

What are common applications of fiberglass fabrication?

Fiberglass fabrication is used in construction (panels, cladding), transportation (body panels, RV components), aerospace (radomes, supports), marine (boat hulls), sports equipment (kayaks, hockey sticks), industrial products (storage tanks, ductwork), renewable energy (wind turbine blades), and electrical applications (enclosures, insulating panels).

How do regulations affect fiberglass fabrication?

Fiberglass fabrication is governed by OSHA standards for worker safety, EPA regulations for environmental protection, industry-specific certifications (such as ISO 9001 and ASTM standards), and local building codes. Compliance ensures safe handling, quality assurance, and lawful operation.

What are the key benefits of choosing fiberglass fabrication?

Fiberglass fabrication provides excellent strength-to-weight ratio, durability, design flexibility, electrical and thermal insulation properties, customizability, and long-term cost-effectiveness. Advancements in recyclability and sustainable materials are making fiberglass an increasingly attractive choice for many industries.

Should I outsource fiberglass fabrication or manufacture in-house?

In-house fabrication offers control over production but requires significant investment in equipment and skilled technicians. Outsourcing gives access to industry expertise, advanced technology, and can be more cost-effective for specialized or complex projects. The choice depends on your business needs, volume, and required certifications.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services