There are many different fiberglass molding processes, including compression molding, blow molding, rotational molding, injection molding and dip molding, among others. Read More…

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

At Advanced Composites, we take pride in our ability to deliver precision fiberglass fabrication solutions that meet the highest standards of performance and reliability. We have dedicated ourselves to mastering the properties of fiberglass and other composite materials so that we can engineer products that balance strength, durability, and lightweight efficiency.

At Fiberglass Fabricators, we take pride in being a trusted partner for innovative fiberglass solutions. Our work is rooted in a deep understanding of fiberglass as a material that offers strength, versatility, and durability across countless industries. Over the years, we have honed our capabilities to deliver high-quality fiberglass fabrication that meets the precise needs of our customers,...

Our world class steel grates are designed for longevity and usability. We can supply a plethora of secondary operations including: sawing, shearing, forming, welding, punching, drilling, plasma cutting, burning, rolling and more. Our teams have the skills to handle virtually any project that requires extensive custom fabrication. Please give us a call today to learn more information!

More Fiberglass Molding Companies

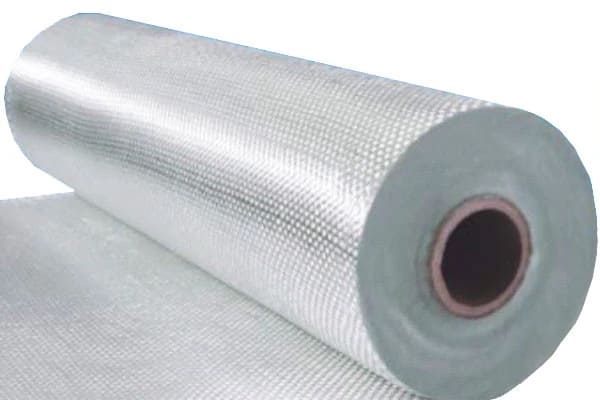

Since its introduction, fiberglass has been used as a reinforcing agent for plastics and as insulation in buildings, homes, stoves, refrigerators, furnaces and in many other applications throughout industry, commerce and in consumer products contexts. Fiberglass moldings are low weight, high strength and scratch resistant. Many boat hulls, go-kart bodies, large storage tanks and automobile parts can be made of molded fiberglass.

Fiberglass molding can be used to make fiberglass sheets, panels, pipes and a wide variety of other shapes. A range of different fiberglass compositions are available to suit the many contexts in which fiberglass moldings are applied. Just a few of these compositions include E-glass, A-glass, E-CR-glass, C-glass and R-glass, each of which features its own properties of strength, durability, UV and corrosion resistance, optical clarity and color.

The three main methods of fiberglass molding are open molding, closed molding, and centrifugal molding. In open molding, a layer of gel coat is applied and cured in a one-piece mold or structure. After being layered into the mold, the fiberglass and sprayed resin are allowed to cure. During closed molding the initial gel coat is applied in a two-part mold.

Fibers in the form of chopped fibers or laminated sheets are sprayed or placed in the female part of the mold on top of the gel coat. The part cures after being sealed in the mold by a vacuum and having catalyzed resin injected into the pressurized mold. In centrifugal molding, the gel coat is applied to the sides of a spinning cylindrical mold.

Layer by layer, catalyzed resins saturated with short fibers are sprayed into the mold until the desired thickness is reached. Centrifugal molding is used to form cylindrical products such as pipes and tanks. In all three processes, the end products are extracted from their molds and subject to any necessary surface treatments or other finishing processes.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services