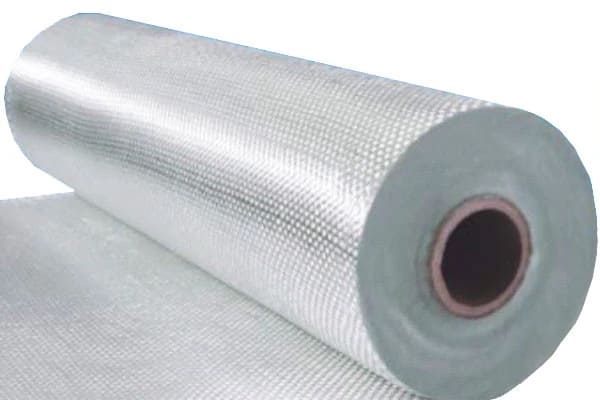

Fiberglass rods are an important material used in a variety of industries. They are made of glass fibers that have been woven into a fabric and then impregnated with a resin, creating a strong and durable material. In this article, we will discuss the variations of fiberglass rods, their limitations, benefits, and applications. Read More…

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

At Advanced Composites, we take pride in our ability to deliver precision fiberglass fabrication solutions that meet the highest standards of performance and reliability. We have dedicated ourselves to mastering the properties of fiberglass and other composite materials so that we can engineer products that balance strength, durability, and lightweight efficiency.

At Fiberglass Fabricators, we take pride in being a trusted partner for innovative fiberglass solutions. Our work is rooted in a deep understanding of fiberglass as a material that offers strength, versatility, and durability across countless industries. Over the years, we have honed our capabilities to deliver high-quality fiberglass fabrication that meets the precise needs of our customers,...

Our world class steel grates are designed for longevity and usability. We can supply a plethora of secondary operations including: sawing, shearing, forming, welding, punching, drilling, plasma cutting, burning, rolling and more. Our teams have the skills to handle virtually any project that requires extensive custom fabrication. Please give us a call today to learn more information!

More Fiberglass Rod Companies

Creating Fiberglass Rods with Pultrusion

Fiberglass rods are manufactured using a highly efficient process known as pultrusion, a continuous production method essential for creating high-strength, lightweight structural profiles. Pultrusion is the preferred technique for producing fiberglass-reinforced polymer (FRP) rods, owing to its ability to ensure consistent quality, precise dimensions, and cost-effective scalability for both small-scale and industrial applications.

The process begins with the selection of high-quality glass fibers, typically sourced from silica or other carefully chosen minerals. These fibers are integral to the resulting product’s tensile strength and durability. Next, the fibers are thoroughly coated with a thermosetting resin, such as epoxy or polyester resin, which acts as the matrix material. The combination of fiberglass and resin delivers the hallmark performance characteristics of fiberglass rods, including corrosion resistance and electrical insulation.

The resin-coated fibers are then pulled through a series of specialized dies within a pultrusion machine. These dies not only shape the composite material into a perfectly uniform rod profile but also initiate the curing process, where heat and pressure solidify the resin, producing a continuous, rigid, and robust fiberglass rod.

The pultrusion process is broken down into several critical stages to ensure maximum structural integrity and performance:

- Fiberglass Reinforcement: Continuous strands or rovings provide the core reinforcement, maximizing the rod’s tensile strength and load-bearing capability.

- Resin Impregnation: The glass fiber reinforcement is meticulously impregnated with a liquid resin, which, upon curing, forms a dense matrix, enhancing durability and environmental resistance.

- Pre-Forming: The impregnated fibers are guided through a pre-forming die to establish the desired profile or cross-sectional geometry, whether round, square, or custom-shaped for specialized uses.

- Pultrusion: The composite is continuously pulled through a heated die, where the resin cures rapidly, resulting in a solid, unbroken length of fiberglass rod with superior mechanical properties.

After pultrusion, the newly formed fiberglass rods may undergo further finishing processes such as precision cutting, sanding, and the application of protective coatings (including UV-resistant or fire-retardant finishes) to enhance longevity and meet specific industry or regulatory requirements.

Why Choose Pultruded Fiberglass Rods?

Pultruded fiberglass rods offer unmatched consistency, high volume production, and cost efficiency. Their dimensional accuracy and repeatable mechanical performance make them the preferred choice for a wide range of industries seeking sustainable, maintenance-free solutions.

Variations of Fiberglass Rods

Understanding the types of fiberglass rods available is crucial for selecting the best solution for your application. The primary variations include:

- Solid Fiberglass Rods: Composed entirely of fiberglass and resin, these rods offer maximum strength and are extensively used in electrical insulation, marine hardware, and heavy-duty industrial supports.

- Hollow Fiberglass Rods: Featuring a tubular structure, hollow rods are ideal for applications requiring lightweight components with excellent stiffness, such as in the construction, aerospace, and recreational sectors.

- Pultruded Fiberglass Rods: Manufactured via the pultrusion process, these rods are available in both solid and hollow forms and can be tailored to meet demanding performance specifications for high-performance engineering, wind energy, and infrastructure projects.

- Custom-Profile Fiberglass Rods: Pultrusion technology also enables the creation of unique cross-sectional profiles, such as rectangular, oval, or T-shaped rods, to meet the needs of specialized engineering designs.

- Colored or Coated Fiberglass Rods: Some applications require rods with color coding for identification or with specialty coatings for enhanced UV, chemical, or flame resistance.

Are you looking for the difference between solid and hollow fiberglass rods? Or wondering about the best fiberglass rod type for your industry? Contact a fiberglass rod manufacturer for expert guidance on material selection and customization.

Benefits & Disadvantages of Fiberglass Rods

Advantages of Fiberglass Rods

- Lightweight Yet Strong: Fiberglass rods deliver a superior strength-to-weight ratio, making them easier to transport, install, and handle compared to metal rods, without sacrificing structural performance.

- Corrosion & Chemical Resistance: Unlike steel or aluminum, fiberglass rods do not rust or corrode, making them ideal for use in harsh industrial, marine, and outdoor environments.

- Electrical Insulation: With excellent dielectric properties, fiberglass rods are widely used in applications requiring electrical isolation, such as transmission lines and switchgear supports.

- Thermal Stability: They maintain dimensional stability and mechanical properties over a wide temperature range, enabling use in both low- and high-temperature environments.

- Low Maintenance: Fiberglass rods require little to no maintenance over their service life, reducing total cost of ownership and downtime for repairs.

- Customizable: Fiberglass rods can be easily tailored in terms of diameter, length, color, and finish to suit unique project requirements or branding needs.

- Non-Magnetic & Non-Conductive: Their inherent non-magnetic nature makes them suitable for use near sensitive electronic or MRI equipment.

- Environmentally Friendly: Pultruded fiberglass often contains recyclable content and supports sustainable construction practices.

Disadvantages of Fiberglass Rods

- Brittleness Under Impact: While strong, fiberglass rods can be more brittle than metals and may fracture under sudden, high-impact loads.

- UV Degradation: Prolonged exposure to sunlight can cause some fiberglass rods to degrade; specialty coatings or additives can mitigate this risk.

- Heat and Moisture Sensitivity: Extended exposure to elevated temperatures or humid conditions may affect long-term performance, especially if not properly coated or maintained.

- Cost Considerations: Initial costs can be higher than some traditional materials, but the long-term savings from lower maintenance and longer lifespan often offset the investment.

- Limited Recyclability: Though more environmentally friendly than many composites, recycling fiberglass can be challenging without specialized facilities.

Want to know if fiberglass rods are right for your project? Request a consultation with a fiberglass rod supplier to discuss your specific requirements.

Applications of Fiberglass Rods

Owing to their unique combination of strength, low weight, and environmental resistance, fiberglass rods are utilized across diverse industries and for numerous applications:

Electrical Insulators

Fiberglass rods serve as critical components in power transmission and distribution systems, including insulator cores and switchgear. Their dielectric properties ensure reliable performance in high-voltage environments, reducing the risk of short circuits and electrical hazards.

Aerospace

In the aerospace sector, fiberglass rods are used to fabricate lightweight structural supports, antennas, and control surfaces. Their high strength-to-weight ratio contributes to fuel efficiency and improved payload capacity while maintaining safety standards.

Marine

Resistant to saltwater, UV radiation, and corrosive agents, fiberglass rods are favored in the marine industry for constructing masts, railings, hull reinforcements, and underwater supports. Their performance in aggressive environments makes them a cost-effective alternative to stainless steel or aluminum.

Automotive

Automotive engineers rely on fiberglass rods for body panels, spoilers, bumper reinforcements, and aerodynamic components. Their lightweight nature contributes to improved vehicle performance and fuel efficiency, while their impact resistance enhances safety.

Sports Equipment

Fiberglass rods are integral to high-performance sports equipment such as fishing rods, golf clubs, hockey sticks, archery bows, and tent poles. Their balance of flexibility and strength enables precise control and durability across recreational and professional uses.

Construction

In construction and civil engineering, fiberglass rods reinforce concrete, act as rebar alternatives, and provide lightweight structural supports for bridges, tunnels, and foundations. Their non-corrosive nature extends infrastructure lifespan in challenging environments.

Wind Energy

Modern wind turbines utilize fiberglass rods in blade construction, benefiting from their high stiffness, fatigue resistance, and ability to withstand continuous cyclical loading. These properties are crucial for maximizing energy output and turbine reliability.

Medical Devices

Medical device manufacturers employ fiberglass rods in surgical instruments, orthopedic braces, and prosthetic components. Their biocompatibility, light weight, and customizable shapes support innovation in patient care and surgical precision.

Other Industrial Uses

Additional applications include agricultural stakes, signage posts, fencing, cable trays, and telecommunications infrastructure. Their adaptability makes fiberglass rods a go-to choice for custom industrial solutions.

Which Fiberglass Rod Suits My Application?

Not sure which fiberglass rod is best for your project, or need help with material selection? Connect with our fiberglass rod specialists to get answers to your technical and application-related questions.

Key Factors When Selecting Fiberglass Rods

Choosing the optimal fiberglass rod for your needs involves evaluating several performance and industry-specific factors:

- Mechanical Properties: Consider required tensile strength, flexural modulus, and impact resistance.

- Environmental Exposure: Assess operating conditions such as UV, moisture, chemicals, or saltwater exposure.

- Diameter & Length: Specify dimensions to ensure compatibility with your application and installation requirements.

- Resin Type: Different resins (epoxy, vinyl ester, polyester) impart unique chemical and thermal properties.

- Regulatory Compliance: Check for certifications such as ASTM, ISO, or UL ratings if needed for safety or industry standards.

- Customization: Determine if you require color coding, special coatings, or unique profiles for your project.

- Budget & Lifecycle Costs: Balance initial purchase price against expected lifespan and maintenance savings.

Would you like a detailed comparison of fiberglass rod properties or a custom quote? Submit your project requirements to our suppliers for tailored recommendations.

Choosing the Correct Fiberglass Rod Supplier

To ensure you achieve the best results when purchasing fiberglass rods, it is crucial to partner with a reputable fiberglass rod supplier who understands your industry and performance needs. Our comprehensive directory connects you with leading fiberglass rod manufacturers and distributors.

- Use our supplier directory to compare fiberglass rod suppliers based on expertise, product range, and manufacturing capabilities.

- Each supplier profile highlights their experience with specific applications, material certifications, and value-added services like custom pultrusion, cutting, and finishing.

- Contact suppliers directly using our integrated RFQ (Request-for-Quote) form to receive competitive pricing and technical support.

- Leverage our patented website previewer to quickly assess supplier websites, product catalogs, and customer reviews for informed decision-making.

- Compare multiple suppliers using a single inquiry form, streamlining your procurement process and saving valuable time.

Questions to Ask When Evaluating Fiberglass Rod Suppliers

- What is your experience with my specific application or industry?

- Can you provide material certifications and compliance documentation?

- What customization options (length, diameter, color, coating) are available?

- How do you ensure quality control during the pultrusion process?

- What are your lead times and minimum order quantities?

- Can you supply technical datasheets or samples for evaluation?

Ready to source high-quality fiberglass rods? Connect with verified suppliers and request a quote to receive tailored offers that meet your project’s specifications.

Frequently Asked Questions About Fiberglass Rods

- What are the main differences between fiberglass rods and carbon fiber rods?

While both are composite materials, fiberglass rods are generally more cost-effective and provide excellent corrosion resistance, whereas carbon fiber rods offer higher stiffness and lighter weight but at a premium price point. - How long do fiberglass rods last?

When properly installed and maintained, fiberglass rods can last decades—often outlasting metal alternatives in corrosive or outdoor environments. - Can fiberglass rods be machined or cut?

Yes, fiberglass rods can be cut, drilled, and machined using standard carbide or diamond-tipped tools, though appropriate safety precautions should be observed. - Are fiberglass rods safe for food or potable water applications?

Certain resins and coatings are certified for food contact; always confirm with your supplier for compliance with FDA or NSF regulations. - How do I specify the right fiberglass rod for my project?

Define your application’s load, environmental, and regulatory requirements, then consult with a knowledgeable supplier for material selection and custom engineering options.

Still have questions? Ask an expert or explore our resources for more guidance on fiberglass rod applications, selection, and sourcing.

Explore More: Related Fiberglass Products & Resources

Take the Next Step: Connect with Fiberglass Rod Suppliers

Whether you are specifying fiberglass rods for a new design, replacing metal components, or seeking a specialized solution for your industry, our supplier directory and resources are here to help. Take advantage of our expertise and start your procurement journey with confidence.

Contact us today to request quotes, discuss your technical requirements, or arrange for custom samples and technical datasheets. Experience the benefits of fiberglass rods in your next project and join the many satisfied customers who rely on composite materials for superior performance and longevity.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services